Low Profile, High Capability

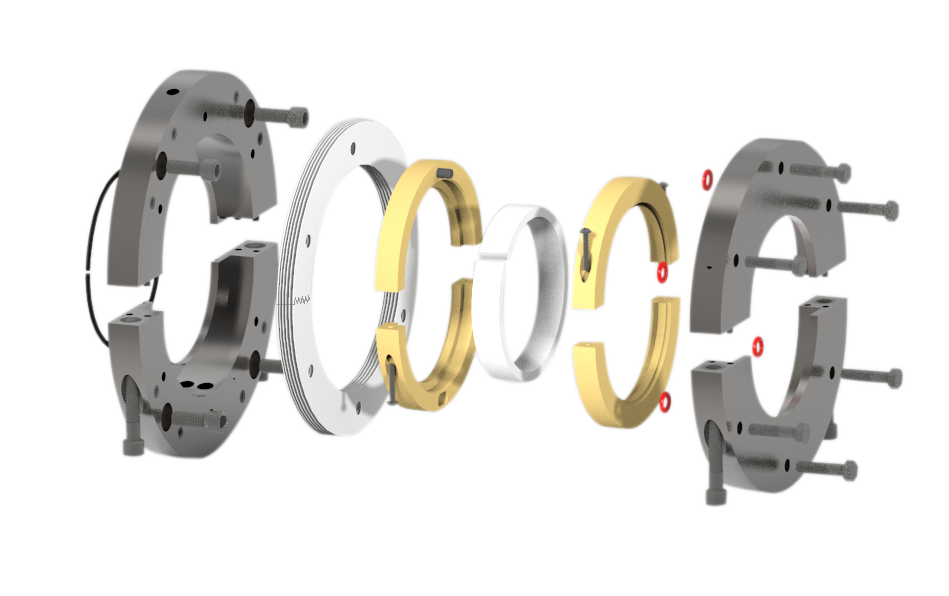

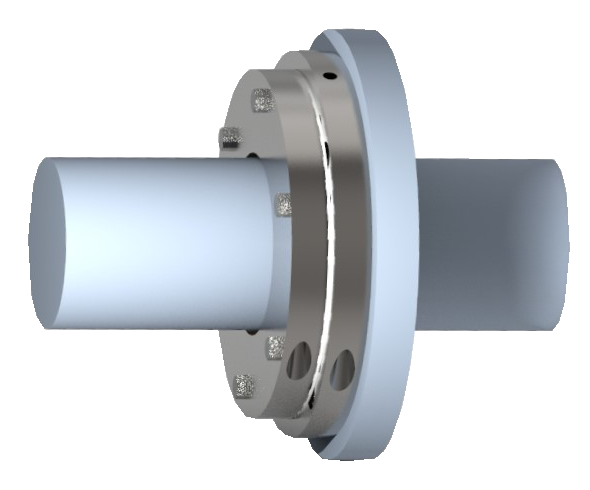

The MECO AH Type-2 model is a split seal, designed to fit in limited space on small to large shaft diameters. The configuration is a soft-face, double mechanical seal using an elastomer drive to rotate bearing-grade synthetic seal faces against fixed, stainless-steel seal faces. A purge gas is used to pneumatically load the seal faces, as well as provide a barrier to further isolate the process from the atmosphere. The AH Type-2 is custom-designed to fit your equipment with minimal or no modifications.

- Fully split

- Pneumatic seal-face loading

- Elastomer driven

- Low profile

AH Type-2

Details

Description

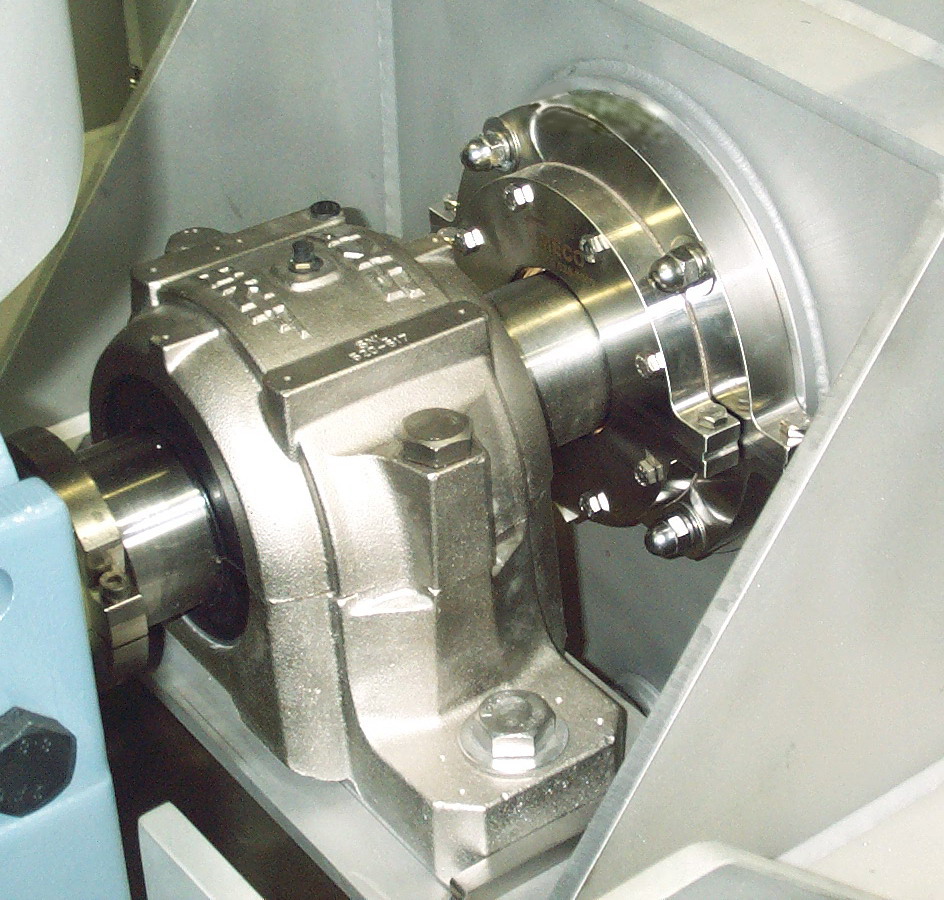

The MECO AH Type-2 seal is a fully-custom, pneumatically loaded shaft seal that answers the common question in process equipment: “How are we going to fit a mechanical seal in such a small space?” Capable of fitting a wide range of shaft sizes, the AH Type-2 is an appropriate selection for screw conveyors, blenders, bucket elevators, and mixers in the bulk conveying, dry plastic and chemical, food mixing and cooking, and food conveying industries. This seal is also applicable in processes where explosivity of the process material is a concern.

Unlike traditional stuffing boxes and packing glands, the AH Type-2 is non-abrasive to the machine’s shaft and will tolerate shaft runout. Wear is transferred to the seal’s replaceable polymer rotors, which are driven by an elastomeric drive ring engaged with the shaft.

How it works

At the heart of the AH Type-2 lies a rotating assembly consisting of an elastomer drive ring, frictionally engaged with the shaft and captured between two soft-faced rotors. These rotating components turn with the shaft inside of a cavity created by two stationary stainless-steel seal faces (stators). By completely tightening these stators, the rotors are compressed and squeeze the drive elastomer to the shaft forming an airtight seal, as well as providing full contact between the stators and rotors.

The seal cavity is typically charged with compressed gas, acting as a barrier fluid between the process and the atmosphere, as well as working to expel debris that may migrate onto the seal faces. Additionally, the gas purge provides pneumatic loading of the seal faces. The two stators are separated by a stack of 1/64” (0.40mm) thick shimming gaskets that provide adjustability to compensate for natural wear of the rotors.

Maintenance

Included with the AH Type-2 are a pressure regulator to control seal cavity pressure and a pressure gauge to monitor actual cavity pressure. The pressure gauge serves as a diagnostic tool to not only assess seal performance, but also check installation integrity. An access port at the bottom of the seal is typically outfitted with a ball valve so the seal’s cavity can be blown free of contaminants.

When a drop in seal cavity pressure is experienced, the seal should be inspected for wear by separating the seal’s stators. Adjusting gasket shims can be removed one at a time, restoring the face loading of the seal by decreasing the distance between the seal’s stators. Fully-split rebuild kits are available, allowing all consumable parts of the seal to be replaced without the need for removing bearings or drives from the machine.

Construction

The standard configuration of the AH Type-2 seal uses 300 series stainless-steel housings with integral stators, that are polished to a high standard of finish to serve as the stationary seal face. Where application parameters require it and available space permits it, the housings may be manufactured with replaceable stainless-steel stators and aluminum housings.

Rotors and elastomers are selected from a variety of bearing-grade polymers and rubbers, with many food-grade materials available.

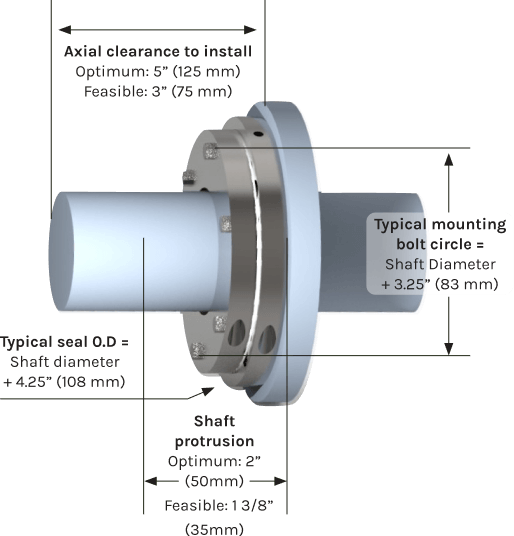

Sizing Chart

Dimensions will vary according to each application, but typical spatial dimensions with respect to the shaft diameter are illustrated in the chart below. Seals are not forced to fit your equipment, but designed specifically for your equipment.

Documentation

Need More Information or a Custom Quote?