The Slurry Sealing Solution

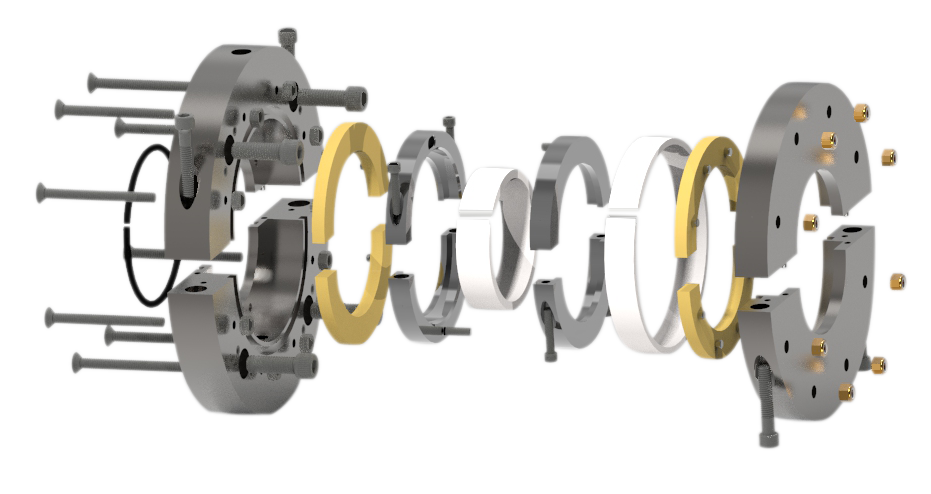

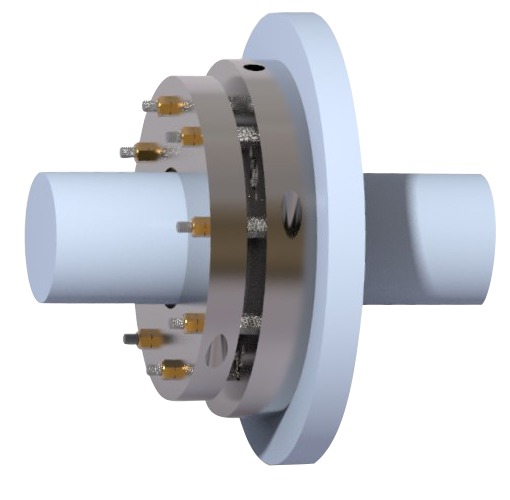

The MECO EA Type-1 is a fully-split design best used for sealing wet, abrasive slurries. A pair of stainless-steel rotors are driven by an elastomer ring against fixed, bearing-grade polymeric stationary seal faces, which are built into split stainless-steel housings. Captured between these housings is an elastomer, used to create a seal cavity where gravity-fed water flushes and cools the chamber with no back pressure applied.

- Fully split

- Elastomer driven

- Water-cooled

- Easily adjustable

EA Type-1

Details

Description

Where axial or linear space is limited, the MECO EA Type-1 seal model is the solution for sealing wet abrasive slurries encountered in pulpers, agitators, cylindrical blenders, paddle mixers, holding vessels, flocculators, mixing conveyors and similar rotating equipment. Industry applications include pulp and paper, home building products, sewage and water treatment, biomass and ethanol production, as well as other processes handling water slurries. They withstand the abuse of shock loading, high shaft runout and abrasives often associated with pulpers recycling office paper and old corrugated containers (OCC). The entire seal assembly is fully-split and serviceable onsite, as well as externally adjustable without disassembly.

How it works

Mechanically akin to a thrust washer, the seal utilizes an elastomer to interlock two rotating stainless-steel seal faces, or “rotors”, with the shaft to provide the rotating thrust washer element, while forming a watertight seal at the shaft. Fixed, self-lubricating polymeric stationary seal faces, or “stators”, are built into two fully-split stainless-steel housings. These are set at right angles to the shaft to provide the fixed-element running surfaces, while an elastomer ring creates a seal cavity for a water flush to flow through at zero pressure. This flush not only draws away heat from the internals of the seal, but also any process material that may have migrated onto the seal faces.

This seal is calibrated on-site to achieve designed seal face pressure and adjusted via external fasteners on the seal’s housing. Instructions for the calibration process are provided with each seal.

Maintenance

Periodic inspection of the seal’s flush water to confirm it is free-flowing is recommended to maximize service life. Over time as the polymer seal faces wear and process fluid clouds the flush water, an adjustment or inspection of the seal is necessary. Without emptying the vessel, the seal is manually adjusted for wear by measuring the distance between the two housings and uniformly reducing it by a set amount. By reviewing the appearance and temperature of the flush water, as well as the seal’s ability to withstand back pressure for a short period of time, the user is able to determine if the seal has been adjusted or installed correctly.

Once the seal will no longer contain flush water or is no longer able to be adjusted, a rebuild is needed. All softer wear components of the seal are available in a rebuild kit, which is supplied fully-split for ease of installation. Stainless-steel seal faces may be replaced and returned to the factory for refurbishment.

Construction

Designed to offer a long service life with chemical compatibility in mind, the EA Type-1 seal is comprised of stainless-steel housings and rotating seal faces (typically 316L stainless-steel housings, 17-4 stainless-steel rotors, with others available), high-performance bearing-grade polymer stators (choose from one of MECO’s inherently lubricated PTFE or PEEK blends), and durable elastomers such as EPDM (most common), Viton®, and nitrile. FDA-compliant options are available upon request.

Materials are chosen based on the requirements of your application, and special requests are often feasible.

Viton® is a registered trademark of The Chemours Company FC, LLC.

Sizing Chart

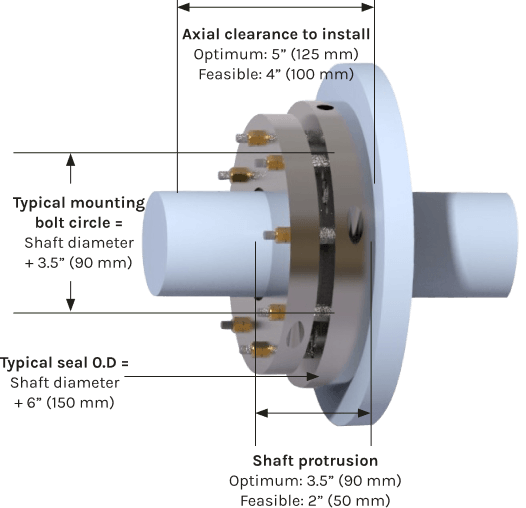

Dimensions will vary according to each application, but typical spatial dimensions with respect to the shaft diameter are illustrated in the chart below. Seals are not forced to fit your equipment, but designed specifically for your equipment.

Documentation

Need More Information or a Custom Quote?