Adjustability Without Disassembly

The MECO EA Type-2 model seal is well suited for many sealing applications operating at low to moderate shaft speeds, and for shafts of various sizes. This seal uses full-contact, soft-face mechanical sealing technology, without the need for a fluid barrier between the seal faces. Providing superior performance, high durability, and quality workmanship, the EA Type-2 is an ideal candidate for sealing machinery in vacuum, steady-state, and infrequent thermal expansion service.

- Fully split

- Elastomer driven

- Gas-purged

- Easily adjustable

EA Type-2

Details

Description

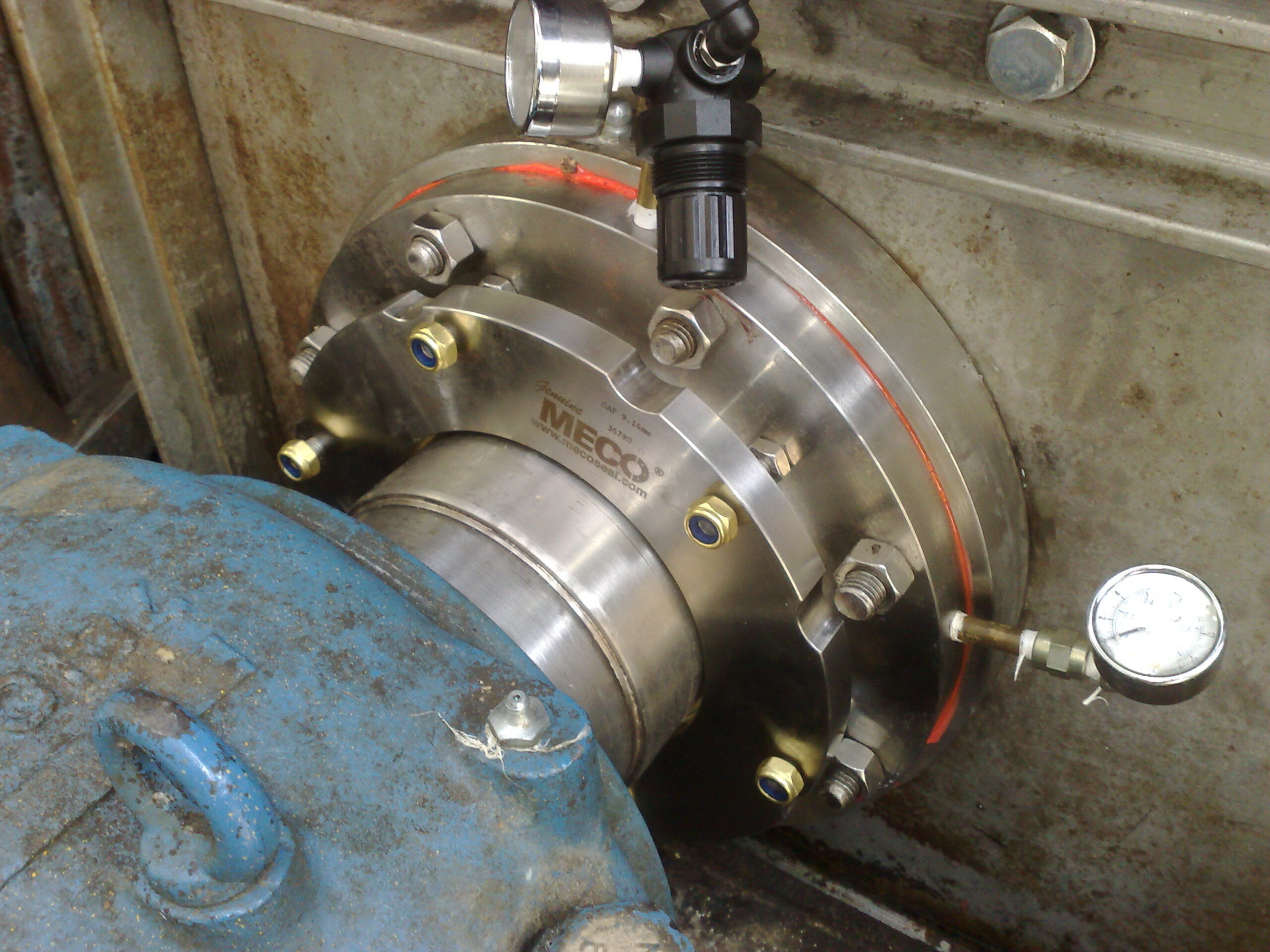

Used on machinery such as large solvent extractors, pressurized conveyors, holding tanks, and others, the EA Type-2 seal is a fully split assembly designed to save users time and money on installation and maintenance. Where dimensional constraints are tight, this seal is also used on some blenders, dryers, and sigma mixers. Common industries that use the EA Type-2 are plastics, oilseed processing, chemical manufacturing, carbon anode fabrication, metals, pharmaceuticals, and food processing.

Being externally adjustable, the EA Type-2 is able to be maintained without the need for emptying the process vessel. The seal is appropriate for vacuum service and steady-state applications with infrequent thermal expansion or pressure changes. For applications with frequent thermal cycles, pressure cycles and/or aggressive chemicals, the MECO Model EP Type-3 seal can be a better match.

How it works

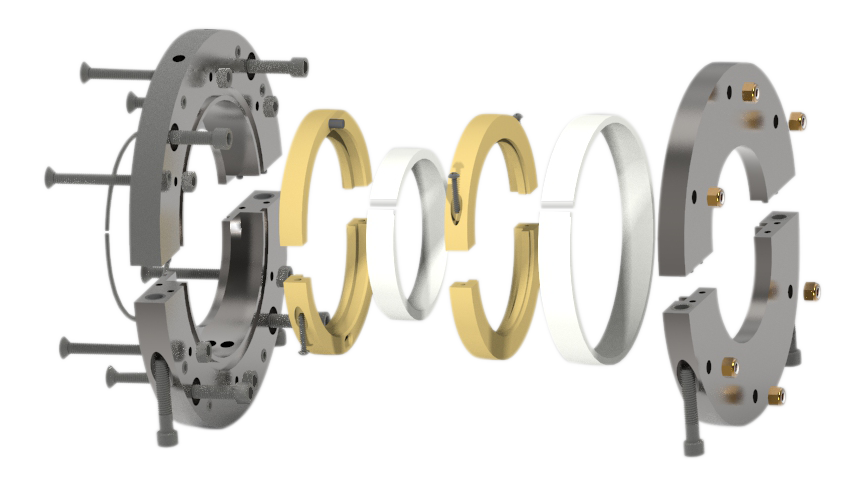

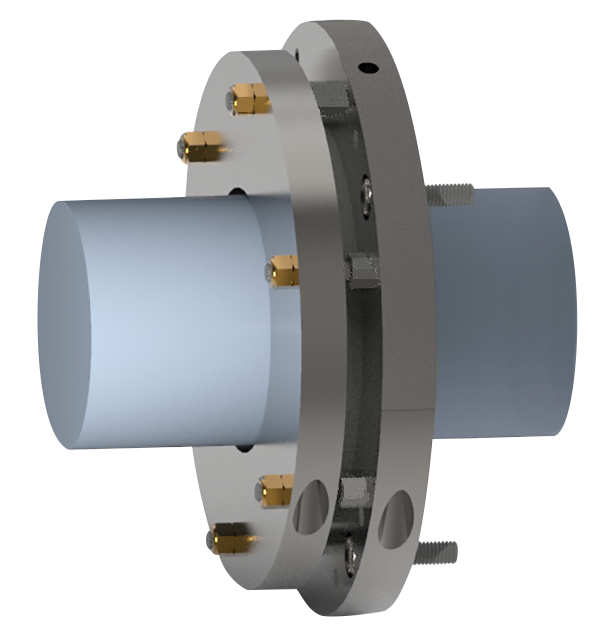

Designed to replace standard stuffing boxes and packing glands, the seal incorporates separate inboard and outboard housings, each containing an integral or replaceable stationary seal face (stator). Between these housings is the rotating seal face assembly consisting of two polymer rotors, interlocked with the shaft via a central driving elastomer that forms an airtight seal.

Seal face loading is controlled by an adjusting gasket that permits the distance between the two housing to be varied. The adjusting gasket also creates a seal cavity for a barrier gas to be contained, which provides pneumatic seal face loading as well as an effective way to check installation integrity and monitor seal performance. As the seal wears over time, seal face loading can be restored to the factory specification by shortening the distance between the two housings.

Maintenance

Included with the seal are a pressure regulator and gauge system to supply and monitor the purge gas (air or an inert gas) to the seal. Performance is monitored by comparing the regulated purge gas pressure entering the seal with the actual gas pressure contained in the cavity. Over time, gas pressure in the seal cavity will gradually reduce as the sacrificial elements of the seal wear. Adjustment is achieved by tightening each of the seal’s assembly fasteners by a uniform amount, ensuring that the seal faces remain parallel to each other and perpendicular to the shaft.

Once seal cavity pressure can no longer be maintained through adjustment, the rotating seal face assembly may be replaced with fully-split components in a rebuild kit, eliminating the need for removal of drives or bearings.

Construction

The standard configuration of the EA Type-2 seal uses an aluminum housing, for the purpose of heat dissipation, and replaceable stainless-steel stators. Where applications require it, housings can be designed in stainless steel with integral stators. Rotors and elastomers are selected from a variety of bearing-grade polymers and rubbers, with many food-grade materials available.

Materials are chosen based on the requirements of your application, and special requests are often feasible.

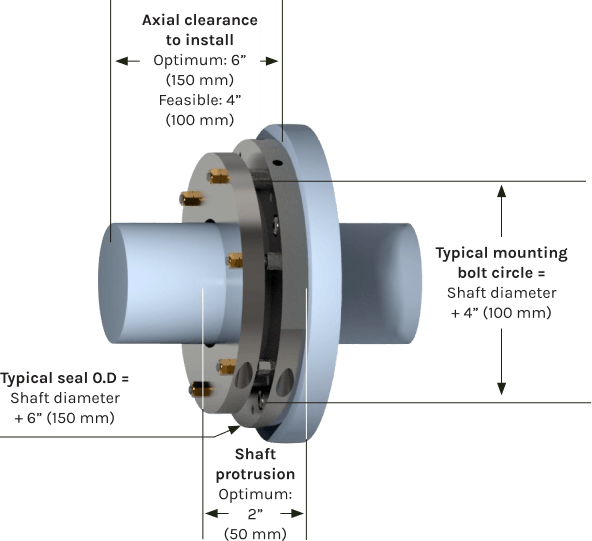

Sizing Chart

Dimensions will vary according to each application, but typical spatial dimensions with respect to the shaft diameter are illustrated in the chart below. Seals are not forced to fit your equipment, but designed specifically for your equipment.

Documentation

Need More Information or a Custom Quote?