Designed in C.E.M.A Standard and Metric Sizes

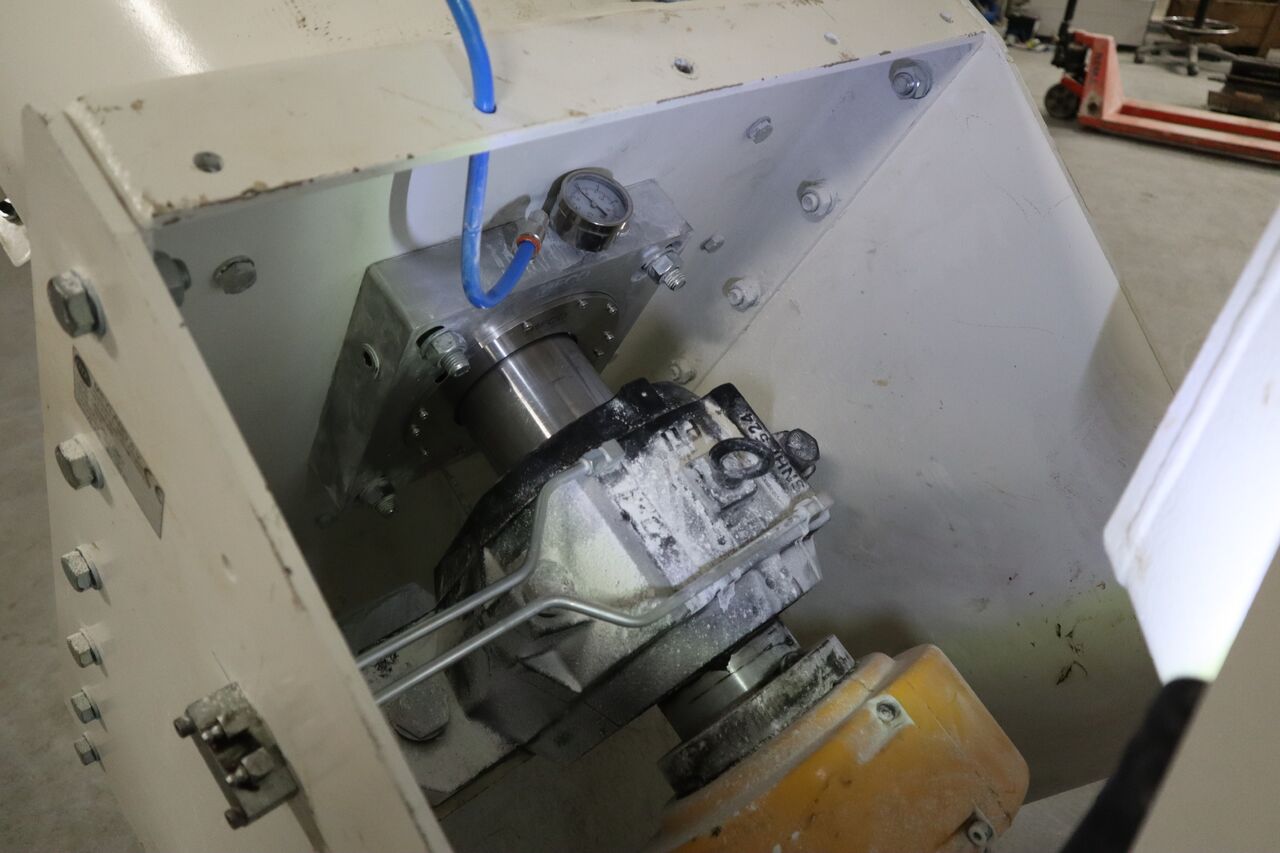

The MECO HA seal is a modular mechanical shaft seal, designed to fit process equipment following Conveyor Equipment Manufacturers Association (C.E.M.A.) standards, with many customizable material options to meet your application’s requirements. A combination of MECO’s classic HB and HC model seals, the HA seal is an air purged seal that can be quickly and easily adjusted without disassembling the seal. Unlike standard stuffing box seals,the HA seal is non-abrasive to the machine’s shaft and can accommodate up to 1/4” of shaft runout.

HA Seal

Details

Description

MECO’s HA seal is highly versatile, with the ability to seal a wide range of products and processes. It is often used for applications with intermediate process temperatures or applications with abrasive products and can be an especially effective solution for sealing smaller shafted equipment experiencing shaft runout. The HA seal can be used on horizontal, inclined, and vertical shafts.

How it works

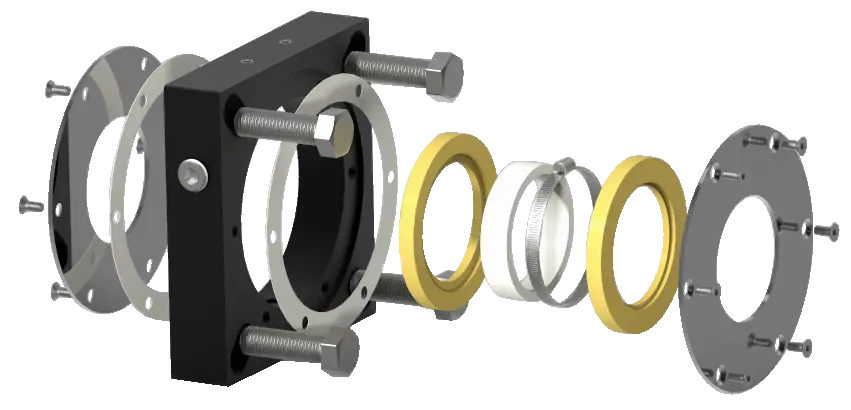

The HA model’s dynamic seal is formed between rotating, polymer seal faces (rotors) and stationary, stainless-steel seal faces (stators). Inside the seal’s solid, square housing, the polymer rotors are frictionally locked into rotation with the machine’s shaft by an elastomer drive ring. The HA seal’s stainless-steel adjusting clamp squeezes the elastomer ring against the shaft, causing it to lengthen axially against the rotating seal faces to provide effective seal face loading. The sliding seal face is also pneumatically loaded by a compressed gas, typically air or an inert gas, which also acts to clear the rotating seal faces of product and debris. In addition, the purge gas helps isolate the process from the atmosphere.

Sizes Available

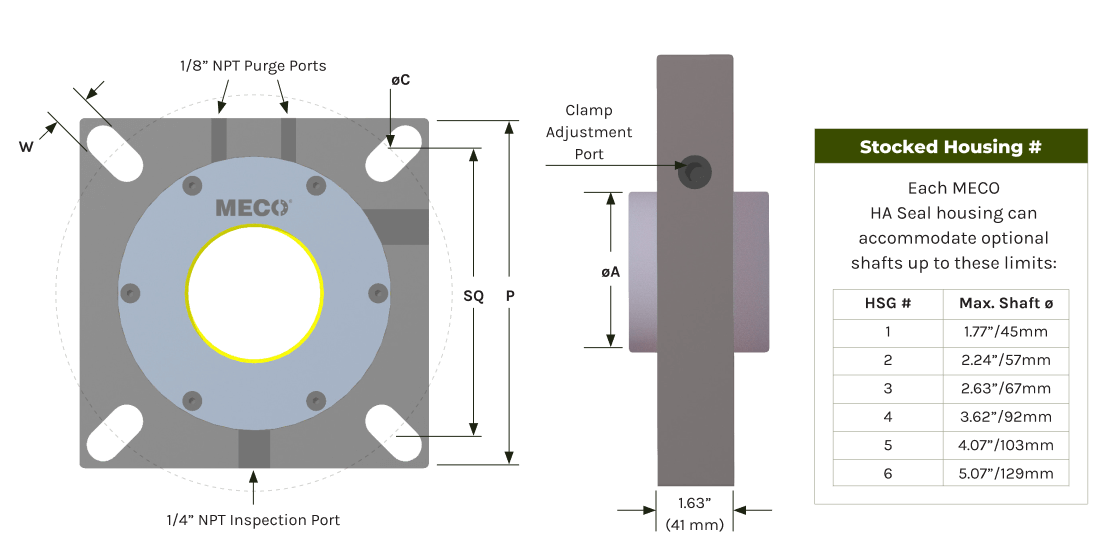

The MECO HA model seal is stocked in 6 standard inch and 13 metric sizes. These 19 seals can be easily converted for other shaft sizes and all fit within the 6 stocked housing (HSG) sizes. This allows the HA model seals to be sized for shaft diameters 5.07” (129mm) and smaller.

Construction

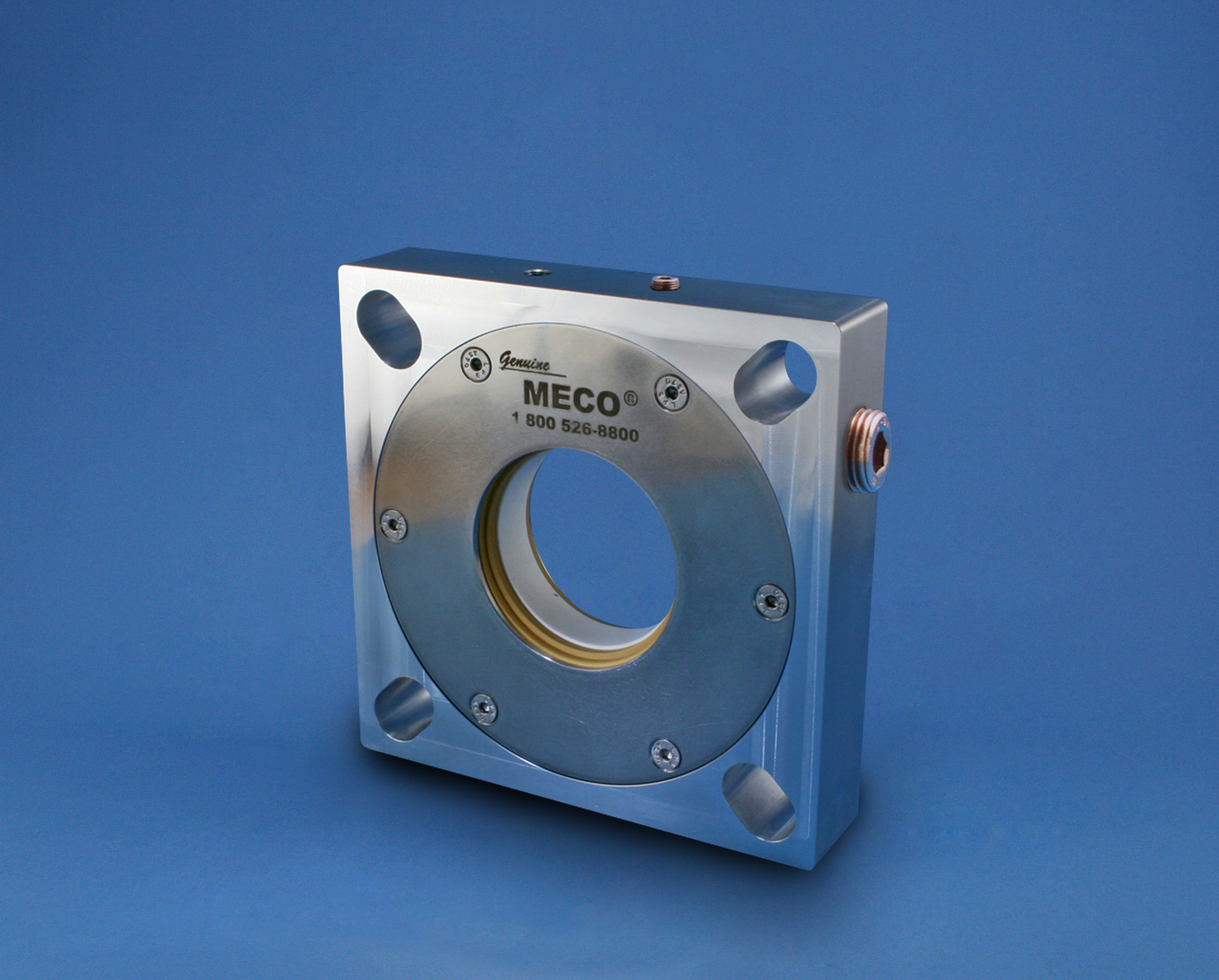

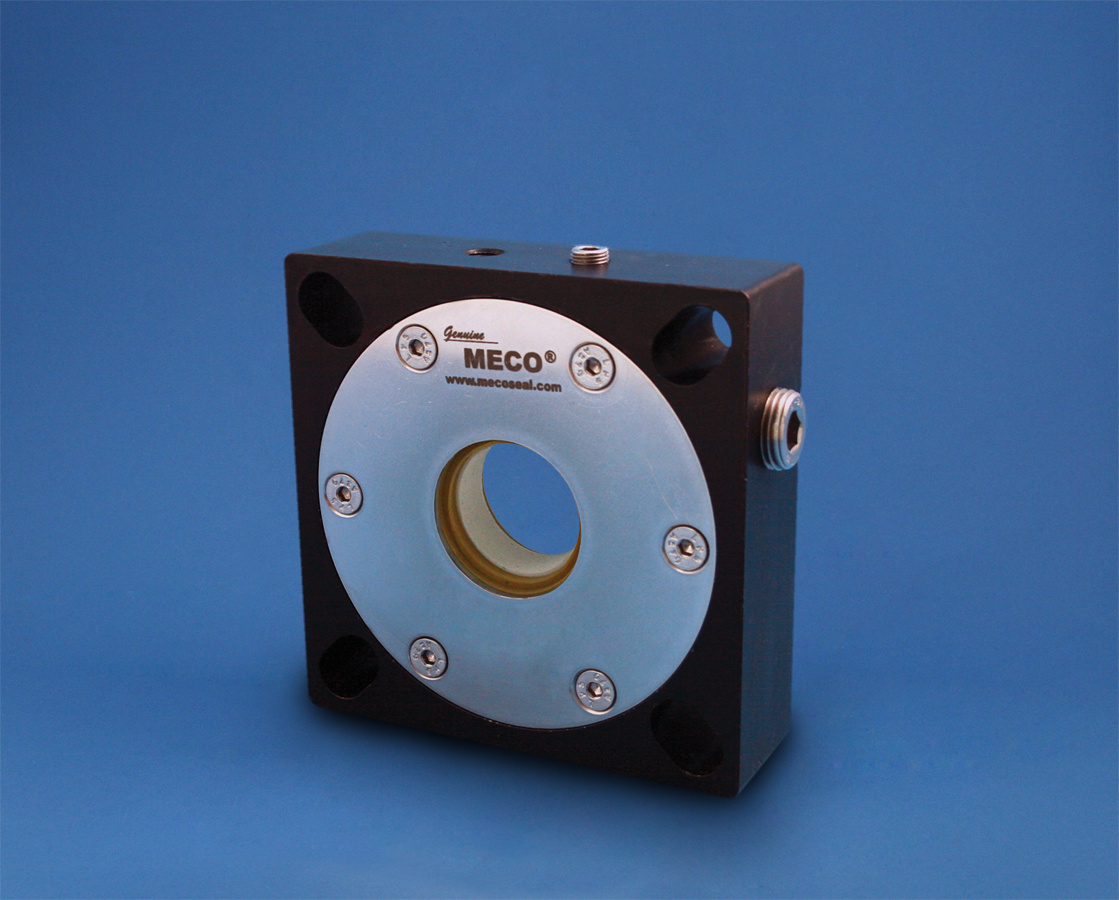

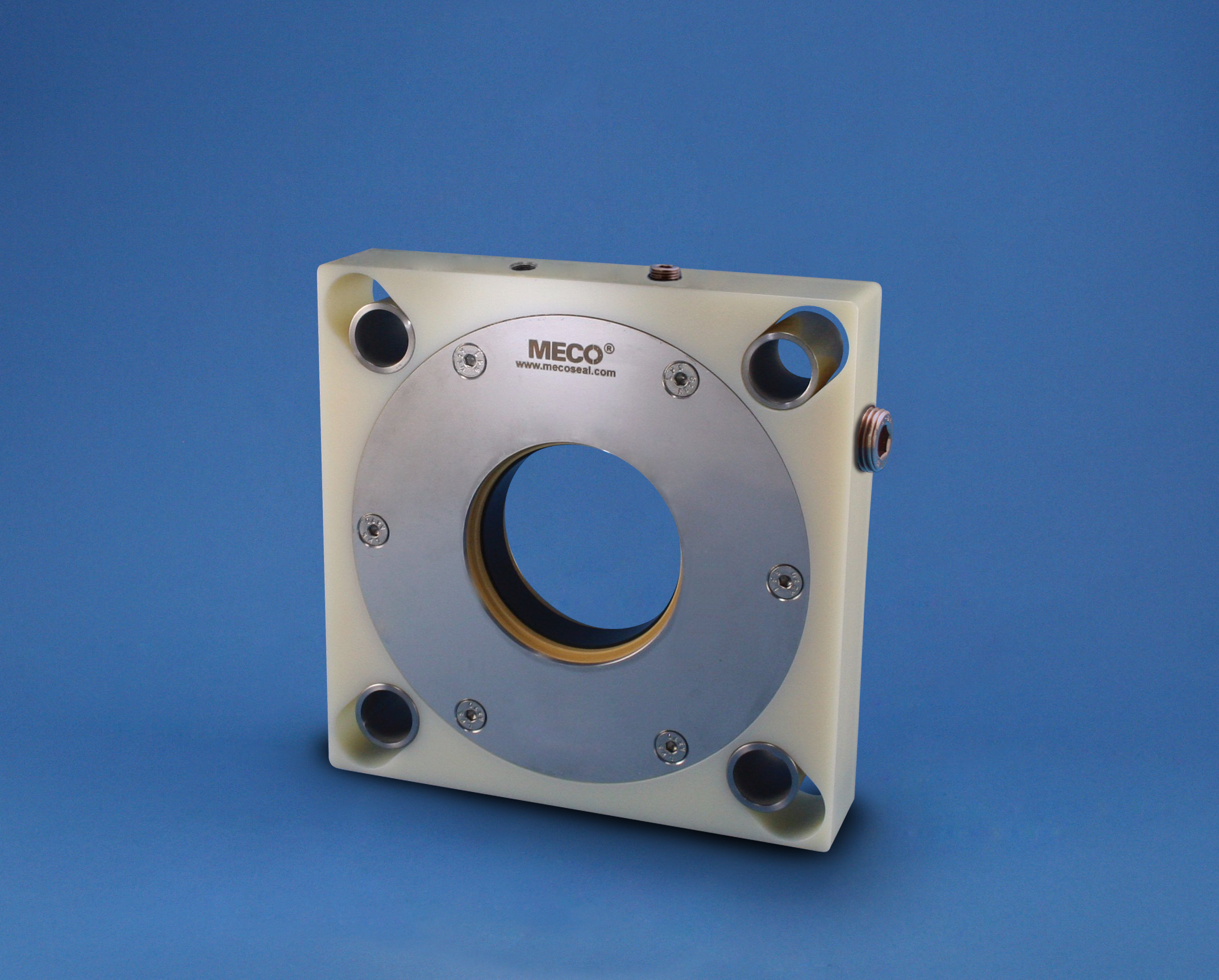

The MECO HA seal’s rugged housing options are designed for long life and offer a range of material options to suit various applications:

- Housing materials: Choose from FDA Nylon, Anodized Aluminum or 316L SS.

- Elastometers: Available in Viton®, FDA white silicone, or EPDM for broad compatibility.

- Stators: Made from 304 (standard) or 316 stainless steel.

- Rotors: The standard material is MECO 3000, a high-performance, bearing grade, polymer-filled PTFE with FDA approval. (No abrasive filler material is added).

- Optional: MECO 3120 (FDA-approved, mineral-filled PTFE) for maximum wear resistance.

- Optional: MECO 3400 (FDA and EU10/2011 polymer-filled PTFE)

- Optional: UHMW Polyethylene for cost-effective, non-abrasive applications or where PTFE is not permitted.

Any of the components may be individually replaced. Unsplit rebuild kits consisting of replacement rotors and drive elastomer are maintained in-stock for immediate shipment. In cases where it is difficult to remove the bearing or drive, convenient, fully-split rebuild kits are available.

Since Woodex-MECO’s seal division manufactures many custom shaft seals, we have the capability to fabricate from sourceable materials when required.

Viton® is a registered trademark of The Chemours Company FC, LLC.

Sizing Chart

Documentation

Need More Information or a Custom Quote?