Designed in C.E.M.A Standard and Metric Sizes

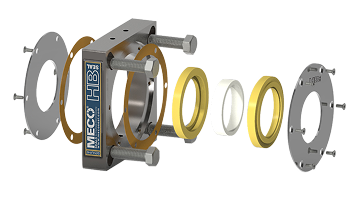

The MECO HB seal model is a full-contact, air-purged soft-face mechanical shaft seal primarily designed for screw conveyors. It uses an elastomer drive to rotate bearing-grade synthetic seal faces against fixed, stainless steel faces. The HB Seal is sized for equipment following standards set by the Conveyor Equipment Manufacturers’ Association (C.E.M.A.) and metric equivalents.

- Air-purged

- Economical

- Fully split repair kits

- Shaft runout capability

HB Seal

Details

Description

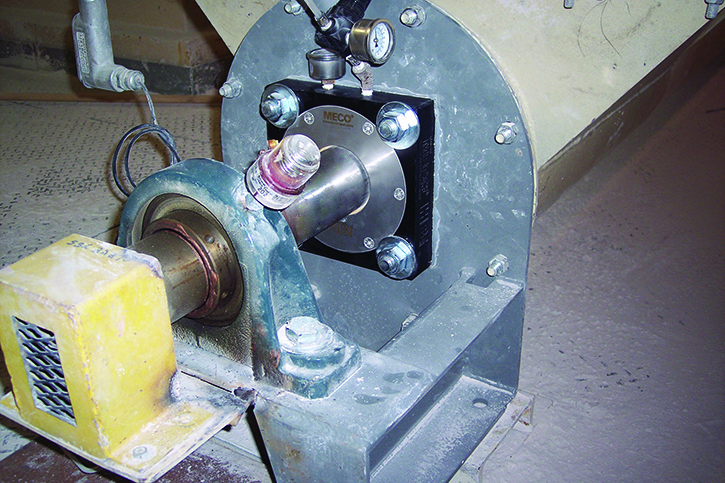

The MECO HB Seal model is ideal for screw conveyors/scrolls, small blenders, bucket elevators, and similar rotating equipment used in bulk process industries. The HB Seal model is used on horizontal, inclined and vertical shafts for unsplit installations.

How it works

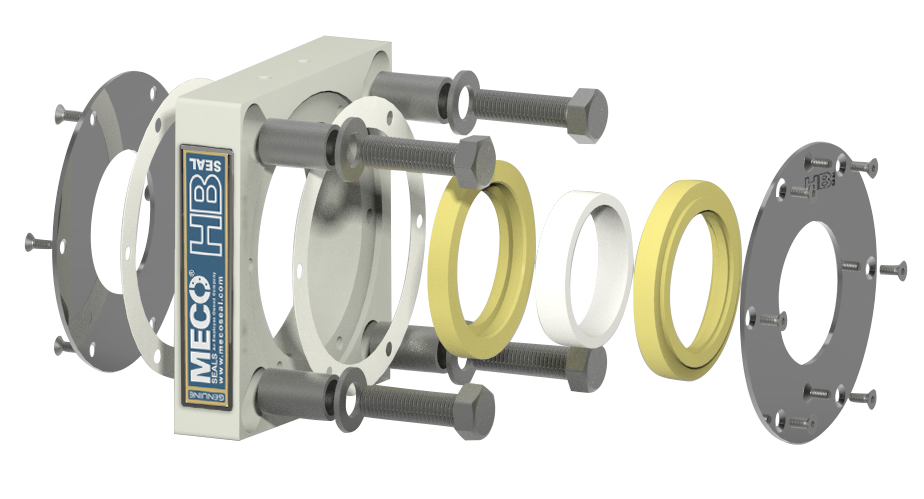

The MECO HB Seal replaces standard waste pack housings. It is made with a heavy, metal or FDA nylon housing that cannot be crushed by an over-tightened flange bearing. Two replaceable stainless steel stationary seal faces attach to the seal housing. Inside is a rotating seal face assembly, consisting of replaceable rotors and drive elastomer. The elastomer and rotors interlock, forming a seal. The low-friction rotating seal faces are at right angles to the shaft and in full contact with the stationary seal faces.

The MECO HB Seal cavity is charged with low-pressure air or gas, which acts as a barrier fluid to provide pneumatic seal face loading. This is a simple and effective way to check installation integrity and monitor seal performance. HB Seals ensure parallelism and flatness to maximize product containment and minimize barrier gas consumption. Alternatively, the HB seal may be reconfigured to operate air-free, using a hose clamp to energize the seal faces. This model is known as our “HC” variation.

Sizes Available

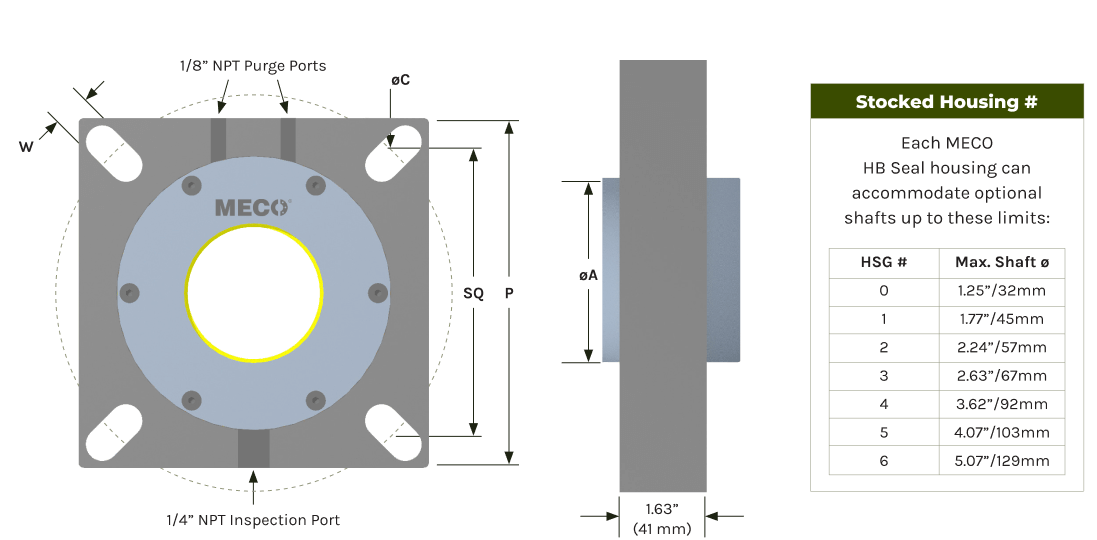

The MECO HB model seal is stocked in 7 standard inch and 13 metric sizes. These 20 seals can be easily converted for other shaft sizes and all fit within the 6 stocked housing (HSG) sizes. This allows the HB model seals to be sized for shaft diameters 5.07″ (129mm) and smaller. See the Stocked HSG Housing # Chart below for maximum shaft size for each of the seven housings. HBZ0 size is not available in the HC format or with the FDA Nylon housing, or with split internal parts.

Construction

The HB seal is built for durability and long life, with a range of material options to suit various applications:

- Housing Materials: Choose from FDA Nylon, Anodized Aluminum, or 316L Stainless Steel.

- Elastomers: Available in Viton®, FDA white silicone, or EPDM for broad compatibility.

- Stators: Made from 304 (standard) or 316 stainless steel.

- Rotors: The standard material is MECO 3000, a high-performance, FDA-approved, polymer-filled PTFE with no abrasive fillers.

- Optional: MECO 3120 (FDA-approved, mineral-filled PTFE) for maximum wear resistance.

- Optional: MECO 3400 (FDA and EU10/2011 polymer-filled PTFE).

- Optional: UHMW Polyethylene for cost-effective, non-abrasive applications or where PTFE is not permitted.

Since Woodex-MECO’s seal division manufactures many custom shaft seals, we have the capability to fabricate from sourceable materials when required.

Viton® is a registered trademark of The Chemours Company FC, LLC.

Sizing Chart

Documentation

Need More Information or a Custom Quote?