Permitting Significant Axial Shaft Motion

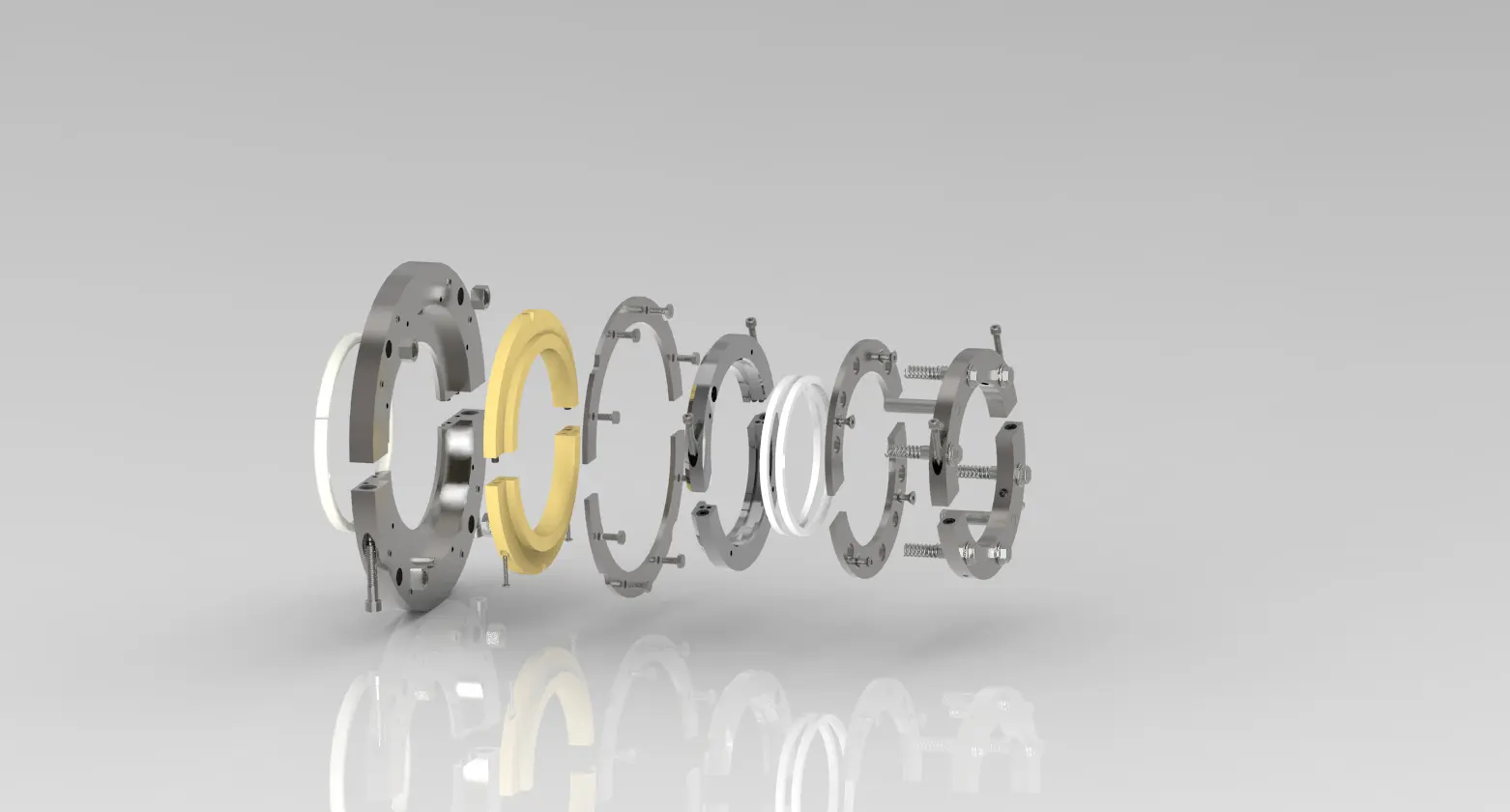

The MECO OFS Type-1 seal is a fully-split seal for vacuum, low pressure, fluid, vapor and abrasive applications. The design tolerates both runout and thermal growth at moderate speeds. The MECO OFS Type-1 places a single, stainless steel rotary seal face, spring-loaded against a single, bearing-grade, polymeric stationary seal face. The seal does not require a barrier fluid. A wide selection of materials is available, allowing service in diverse processes.

The fully-split seal is custom-designed for existing process equipment or can be tailored to OEM or end-users’ wishes.

- Fully split

- Easily cleaned

- Air-free

- Self-adjusting

OFS Type-1

Details

Description

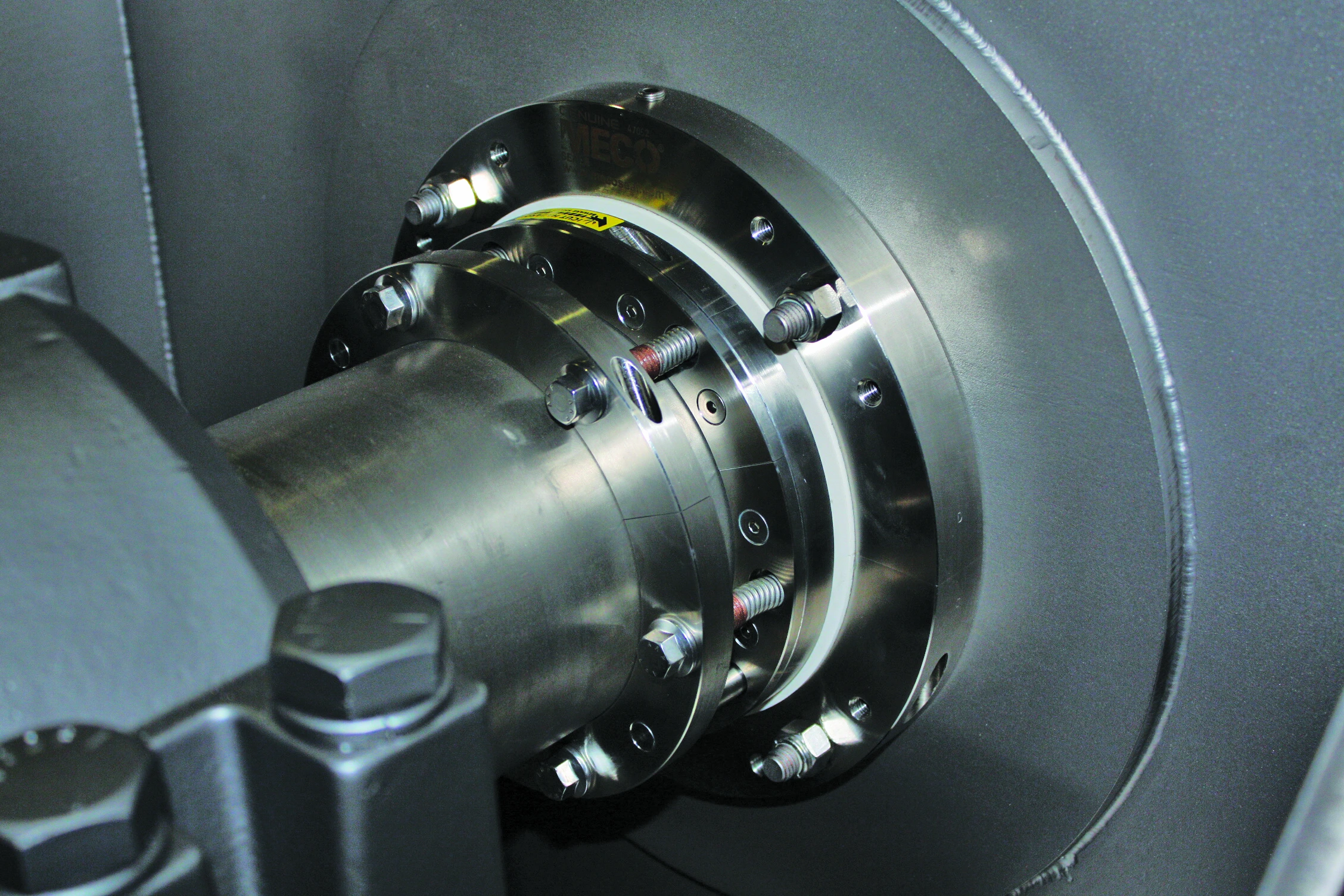

The MECO OFS Type-1 split seal is ideal for top-entry agitators, crystallizers, dryers, pan mixers, blenders, hoppers and similar rotating equipment used in the petrochemical, plastics, metals, minerals and other process industries. The MECO OFS Type-1 seal is used with top-entering and horizontal shafts. The seal has been used with crystallizers operating at cryogenic temperatures, and in an environment with saturated steam under full vacuum and relatively hot conditions. The seal is often used both to keep process materials inside the vessel and also to keep atmospheric oxygen from entering the process. The MECO OFS Type-1 is used in the production of plastic resins and additives, paraxylene, solvent-based ink, VOC vapors and fumes, crystal sugar, industrial chemicals and industrial fermentation processes, as well as hot food cooking and drying applications. Process improvements encompass product and atmosphere containment, product purity, batch time reduction and consistency between batches, extended mean-time-to-repair (MTR), and only two to four hours of installation time once the equipment is prepared. The fully-split assemblies meet chemical compatibility and materials of construction challenges.

How it works

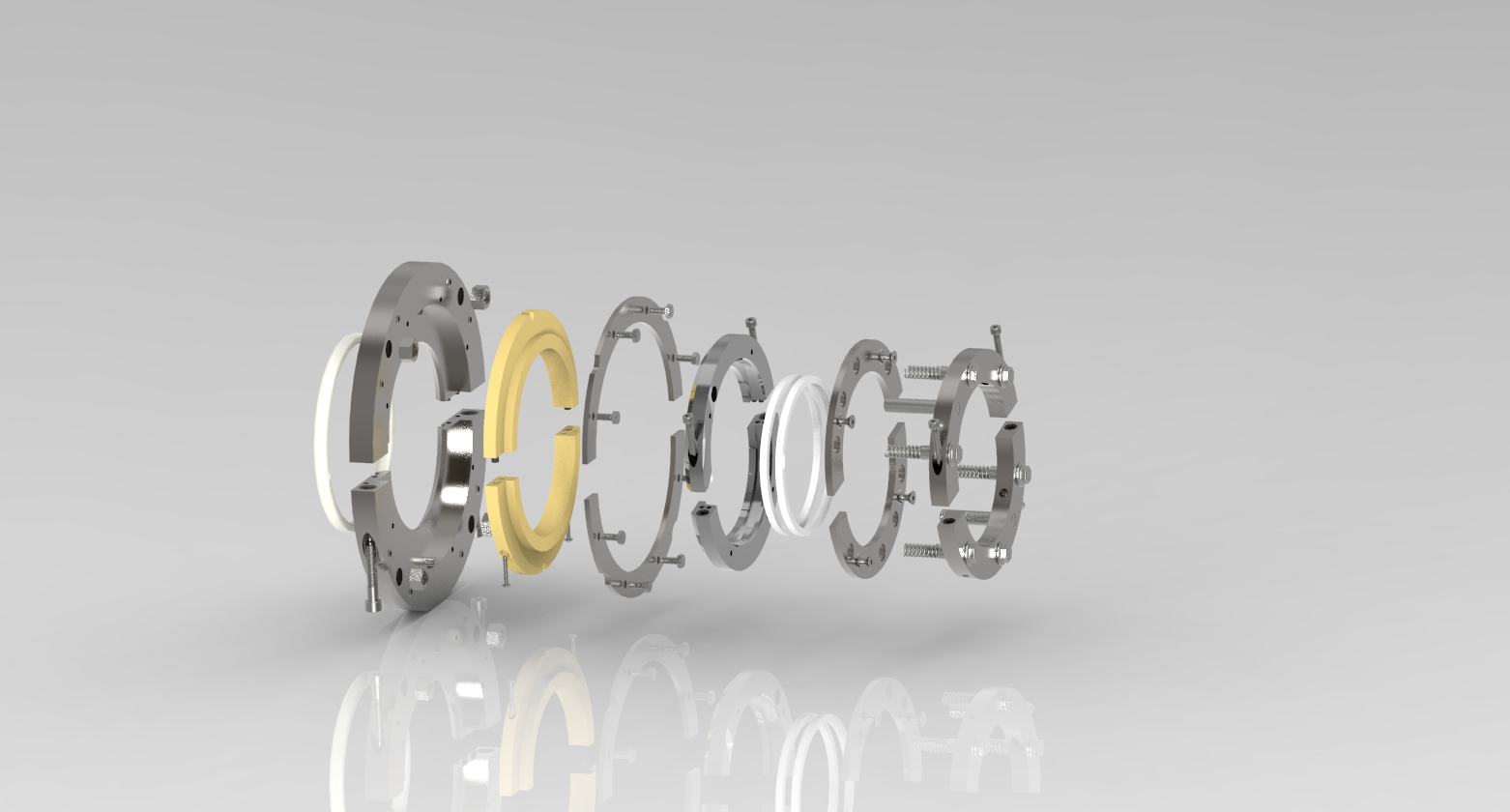

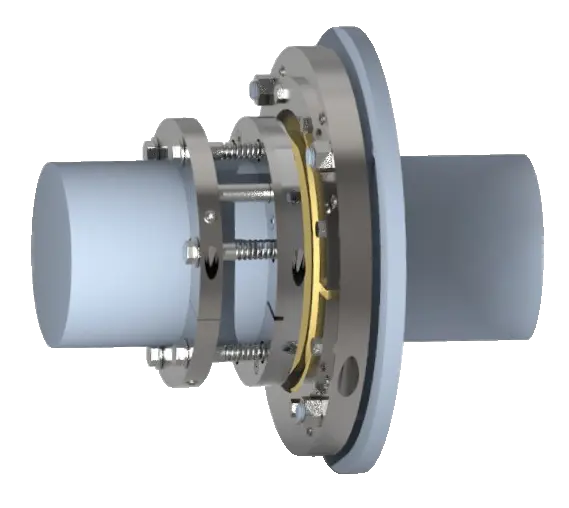

The MECO OFS Type-1 seal replaces stuffing boxes, lip seal housings, hard-face mechanical seals, elastomer-driven seals and unsplit seals. The split seal housing is fitted to your equipment, complete with a split, bearing-grade, synthetic stationary seal face. The rotary seal face is made from stainless steel positioned at a right angle to the shaft and is maintained in contact with the stationary seal face. Sealing along the shaft is accomplished with a static ring of braided packing or an “O”-ring, contained within the inner diameter of the rotating seal face. The rotary seal face is turned by drive pins, fixed to a drive collar which is locked to the shaft. External springs & actuators are attached to the drive collar to load the rotary seal face. The seal designer predetermines the spring calibration, based on application parameters.

Maintenance

Although the external parts of the MECO OFS Type-1 split seal are easily viewed for a quick visual inspection, when installed on top of a 30-foot agitator or behind a shroud, they become out-of-sight, out-of-mind and can be forgotten. As such, the seal rarely receives preventative maintenance, but continues performing as intended.

However, to maximize the mean-time-to-repair (MTR), the seal is easily disassembled for inspection and resetting, as well as replacing any exposed O-rings or packing along with a general wipe down to remove any debris. By loosening the spring actuators and drive collar, the parts may be pulled back for inspection and resetting. Reassembly sets the seal face closing force to original values, accounting for any seal face wear and resetting the seal to a slower wear rate, maximizing the MTR.

Sizes Available

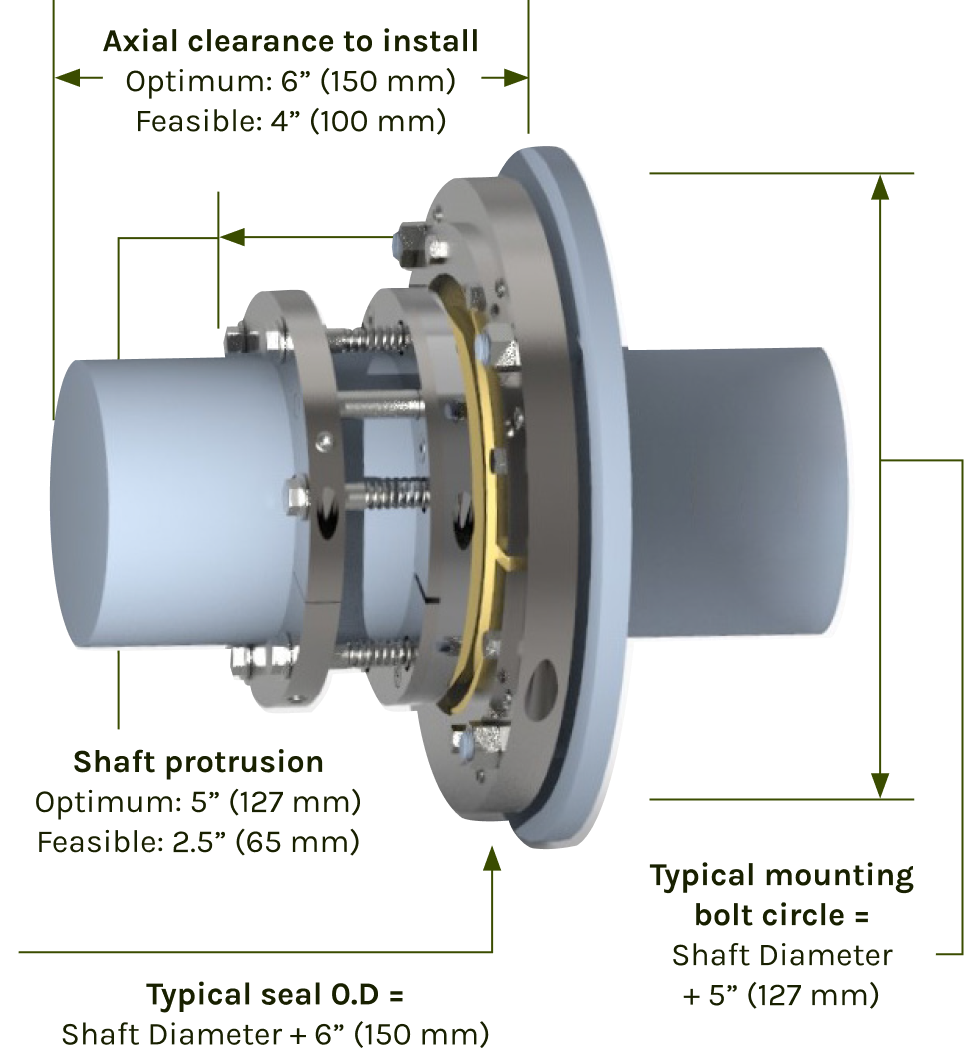

Dimensions will vary according to each application, but typical spatial dimensions with respect to the shaft diameter are shown in the illustration below (see Sizing Chart section). The seals are not forced to fit your equipment but designed with your equipment in the forefront. MECO OFS Type-1 seals are not re-designs of pump seals. They are designed to fit most mounting arrangements specified by OEMs and are designer-friendly, allowing MECO engineers to fit most existing process equipment “as is.” MECO OFS Type-1 seals are built utilizing either S.A.E or metric dimensions and fasteners.

Construction

The OFS Type-1 seal components are designed fully-split and to install within your spatial constraints. They follow MECO’s exacting standards of seamless fit and finish. The design utilizes a stainless steel rotary seal face. The stationary seal face is selected from one of our MECO 3000 series of bearing-grade, PTFE-based blends. We have several polymeric materials available to match the needs of your application. Depending on the application, the static seal component in contact with the shaft may be made of a braided packing or an elastomeric material. The drive assembly is made of stainless steel. The housing is either aluminum or stainless steel. MECO seals may be fabricated from a wide variety of suitable materials. This offers great flexibility to meet the demands of your application.

Additional seal features may be considered. In some instances, fitting the stuffing box with a steady bearing or packing can reduce runout. In some applications a barrier ring, mounted into the back of the seal housing, may help to maximize MTR. An optional port, entering in front of the stationary seal face, is a feature requested for some applications. The port provides a way to introduce an inert gas blanket or an air sweep in front of the seal and into the process vessel. Additionally, the port may be used to attach a pressure indicator for monitoring process pressure trends.

Mounting

MECO offers a few options to consider during your application review. You may have specific details for matching to your profile. O-rings, flat gaskets & bedding compounds are typical static sealing options available between the MECO OFS Type-1 seal housing and the mounting surface on your equipment. Jacking screws are an enhancement that help to mount the MECO OFS Type-1 seal’s housing perpendicular to the shaft and control flatness of the stationary seal face. What does your mounting surface and shafting look like? We’ll offer a few options to consider during your application review.

Sizing Chart

OFS TYPE-1 Sizing Chart

Documentation

Need More Information or a Custom Quote?