Quality Sealing When Cleanliness Counts

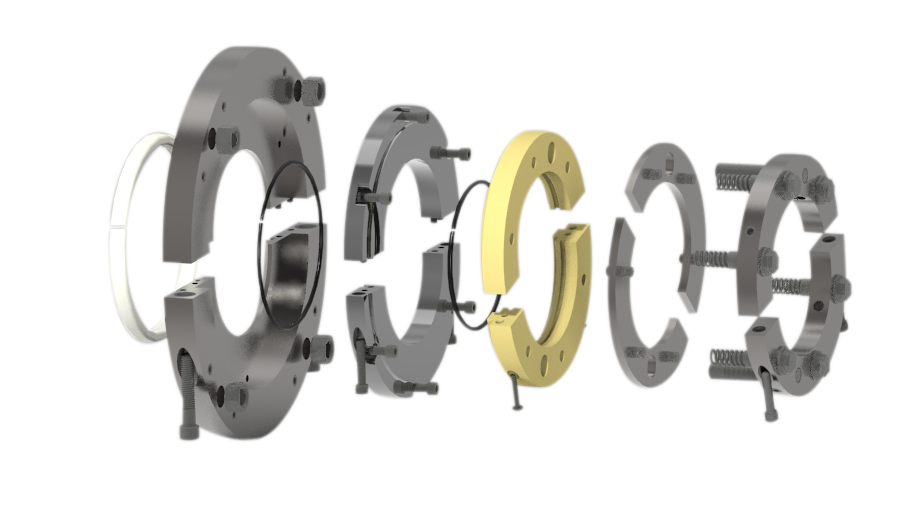

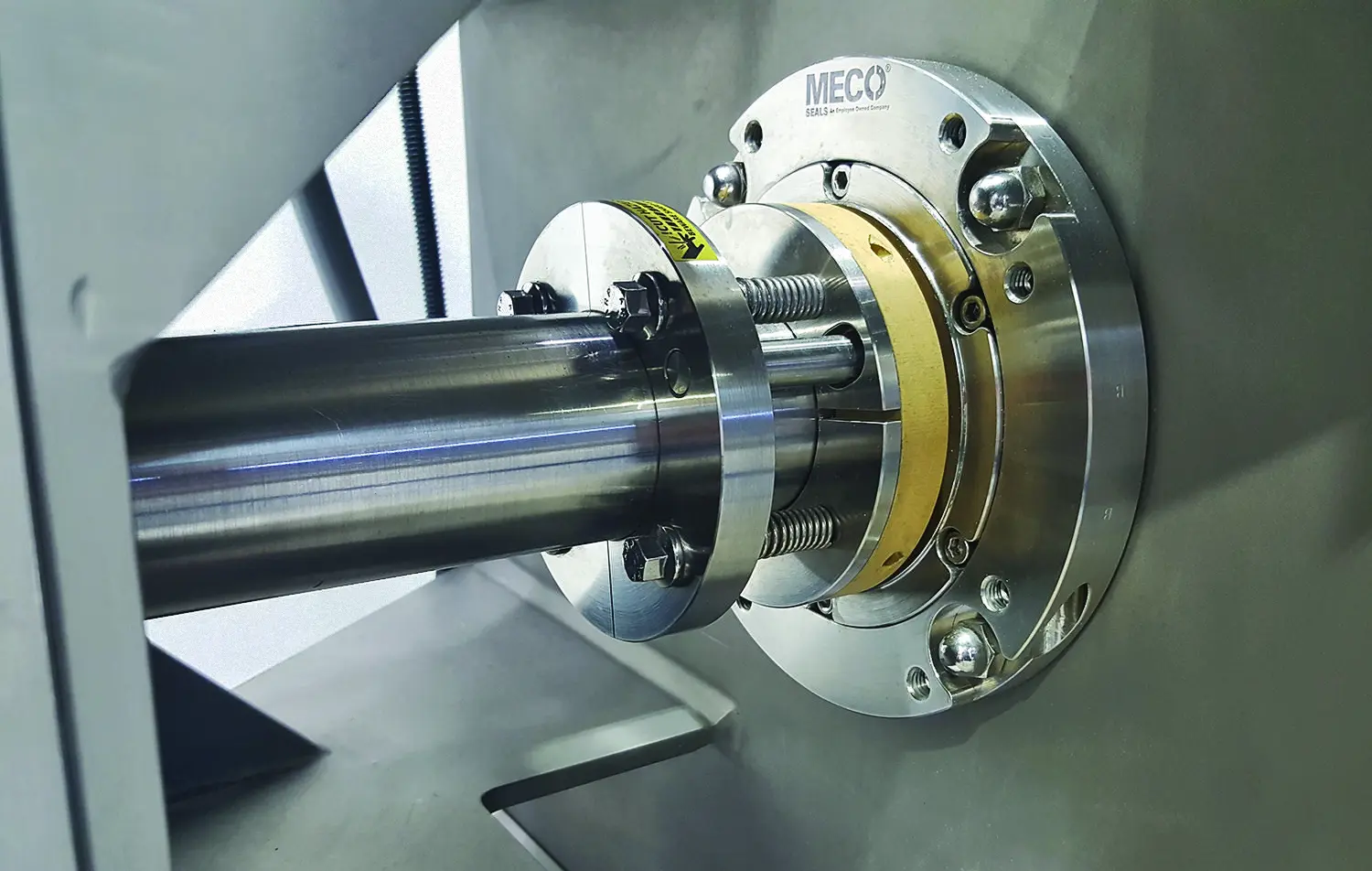

The MECO OFS Type-2 model is a good choice in many sealing applications for low to moderate speed equipment at moderate temperatures. The seal uses full-contact, soft-face mechanical shaft sealing technology, without the need for a barrier fluid. Available in custom sizes to fit most food process equipment, the OFS Type-2 is a fully-split design allowing for easy installation and maintenance.

- Fully split

- Easily cleaned

- Air-free

- Self-adjusting

OFS Type-2

Details

Description

The MECO OFS Type-2 seal model is ideal for blenders, mixers, cookers, conveyors and similar rotating equipment used in the food, pharmaceutical, chemical, plastics, metals, and other bulk process industries. This seal is an appropriate selection for horizontal, inclined, and top-entry shafts. Frequently used in dry powder blending applications, the OFS Type-2 has successfully sealed drink mixes, spices, flavorings, nutrient supplements, plastic and metal powders, and chemicals. It is also widely used for wet mixing applications involving soups, sauces, and pet foods.

Being a single-face seal, the OFS Type-2 does not use a gas purge, allowing users to avoid the costs and headaches associated with compressed gasses. Additionally, the single-face nature of the seal provides the user with hassle-free cleaning – either while assembled on the machine or freely disassembled along the shaft.

How it works

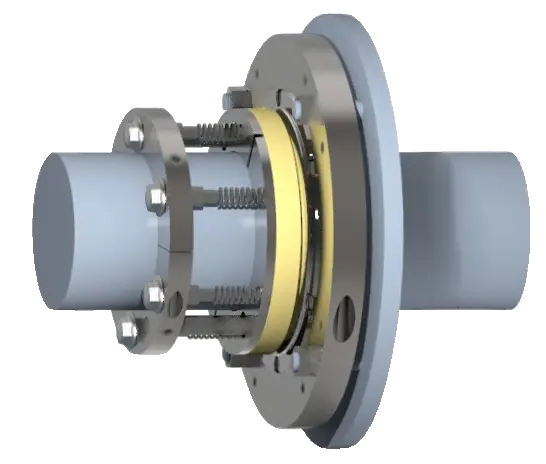

This seal model replaces stuffing boxes, lip seal housings, hard-faced seals, unsplit seals, and others. It is made with a heavy, stainless-steel housing and stationary seal face (stator) that bolts directly to the machine at right angles to the shaft. A low-friction polymeric rotating seal face is maintained in full contact with the stator via load springs and actuators. Sealing along the shaft is accomplished with a static “O”-ring contained in the rotor that turns with the shaft and rotor. The rotary seal face is driven by a drive collar, with large drive pins and self-contained springs. This drive collar locks to the shaft at a distance from the rotor predetermined by designers based on application parameters. Factory calibration is set by fully tightening the spring actuators, providing the seal face closing force.

Maintenance

The OFS Type-2 is easily maintained by monitoring the predetermined distance from drive collar to rotor, as well as by loosening the spring actuators and drive assembly components, allowing parts to be pulled back and seal faces to be inspected and cleaned. Reassembly of the seal to factory specification resets the seal face closing force to original values. All seal components may be washed in-situ, following Current Good Manufacturing Practice (cGMP) regulatory framework.

Construction

Designed for long service-life, the OFS Type-2’s rugged components are selected based on the requirements of your application. Standard configuration uses a stainless-steel housing and stator, bearing-grade polymer rotor, and FDA Viton® “O”-ring. For highly-abrasive process materials, seals may be designed with a replaceable stator insert that is able to be returned for factory refurbishment. Other materials are available, as required by the specific application.

Additional seal features may be considered to maximize mean-time-to-repair (MTR), such as steady bearings to reduce shaft runout, barrier rings or gas blankets behind the seal housing to further isolate the process from the atmosphere, and porting through the front of the stationary seal face to monitor process pressure trends.

Viton® is a registered trademark of The Chemours Company FC, LLC.

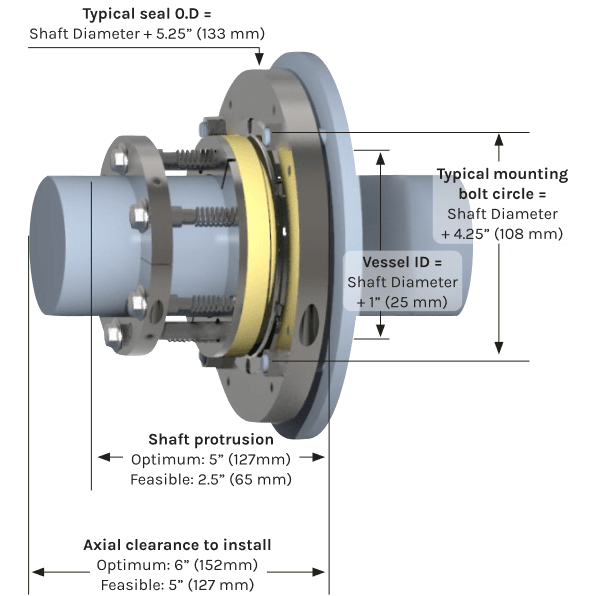

Sizing Chart

Dimensions will vary according to each application, but typical spatial dimensions with respect to the shaft diameter are illustrated in the chart below. Seals are not forced to fit your equipment, but designed specifically for your equipment.

Documentation

Need More Information or a Custom Quote?