Full Contact, Soft Face Mechanical Seal

The MECO OFS Type-2 model is a good choice in many sealing applications for low to moderate speed equipment at moderate temperatures. The OFS Type-2 uses full-contact, soft-face mechanical shaft sealing technology, available in sizes to fit most food process equipment.

- Fully split

- Easily cleaned

- Air-free

- Self-adjusting

OFS Type-2

Details

Description

The MECO OFS Type-2 seal model is ideal for blenders, mixers, cookers, conveyors and similar rotating equipment used in the food, pharmaceutical, chemical, plastics, metals, and other bulk process industries. The MECO OFS Type-2 seal model is used on horizontal, inclined, and top entering shafts for split and unsplit installations. It is frequently used in dry powder blending applications including sugar drink mixes, spices, flavorings, nutrients, plastic and metal powders, and chemicals. It is also used in wet mixing for products like soups, sauces & pet foods.

The single-face MECO OFS Type-2 seal is an air-free design, which allows users to steer clear of the costs and hassles associated with compressed air. The seal is extremely effective in vacuum service.

The MECO OFS Type-2 seal model allows easy, speedy cleaning. The seal may be washed in 10 minutes time while assembled on the blender or freely disassembled along the shaft for cleaning and inspection.

How it works

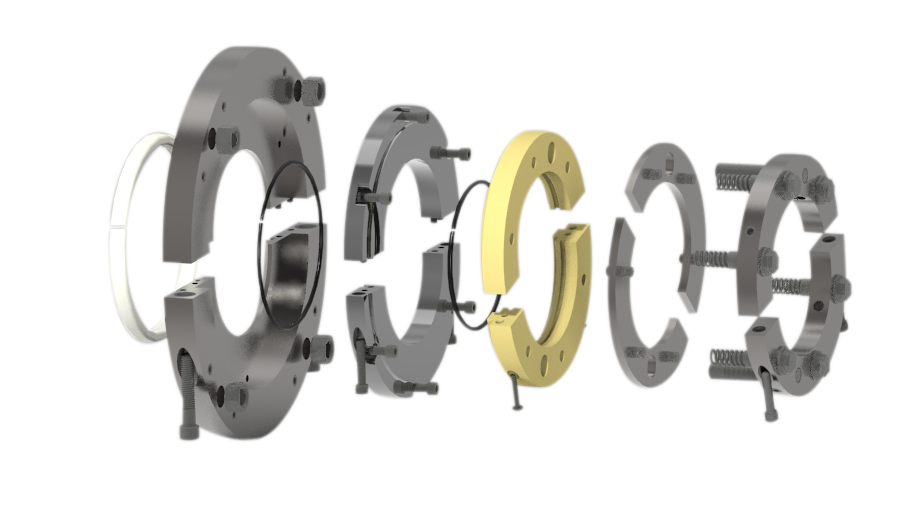

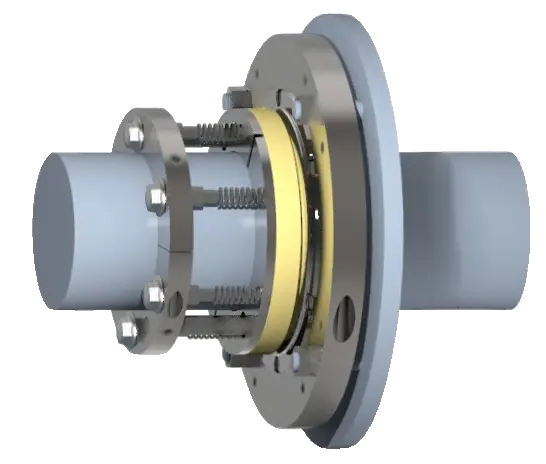

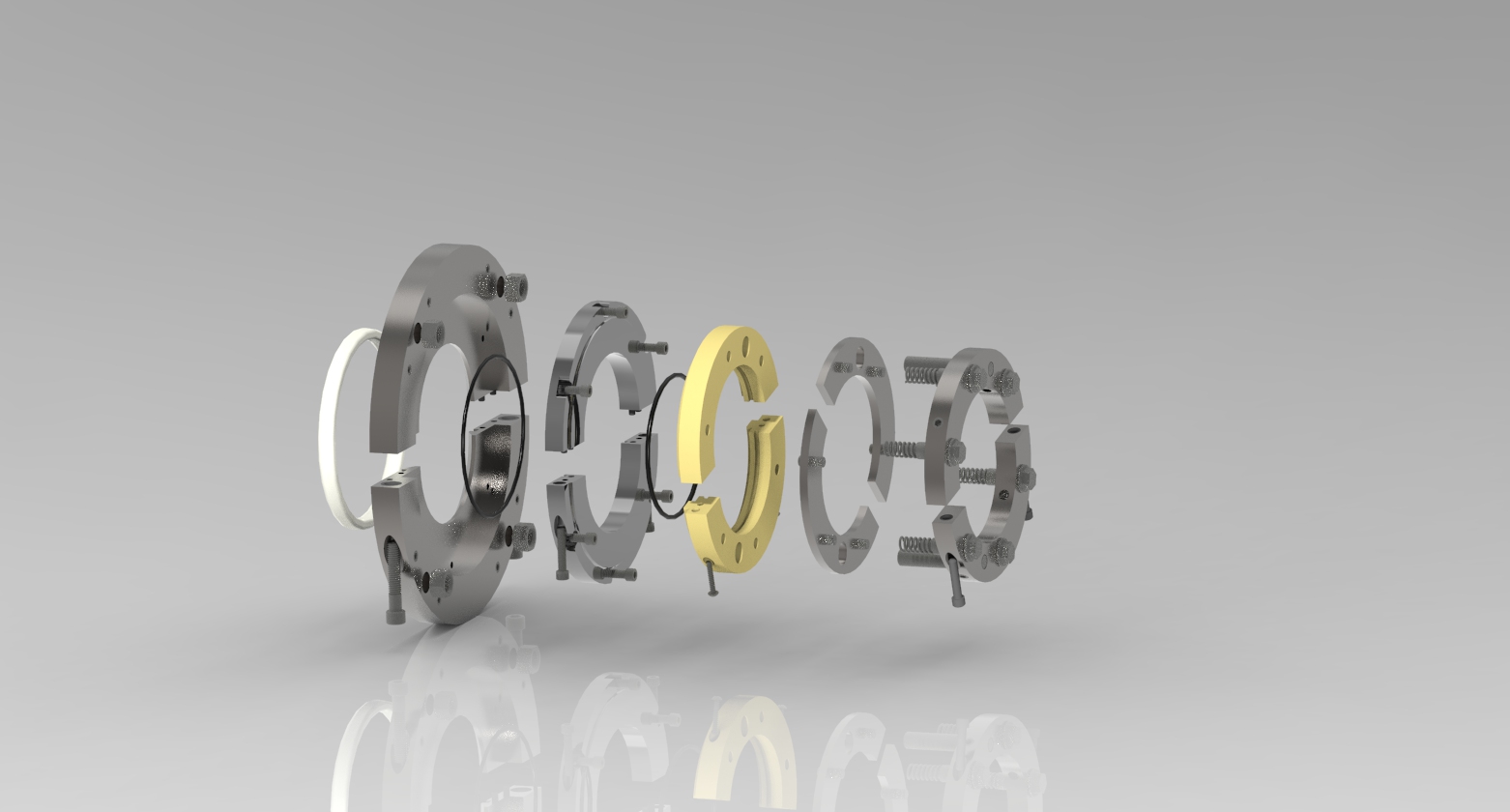

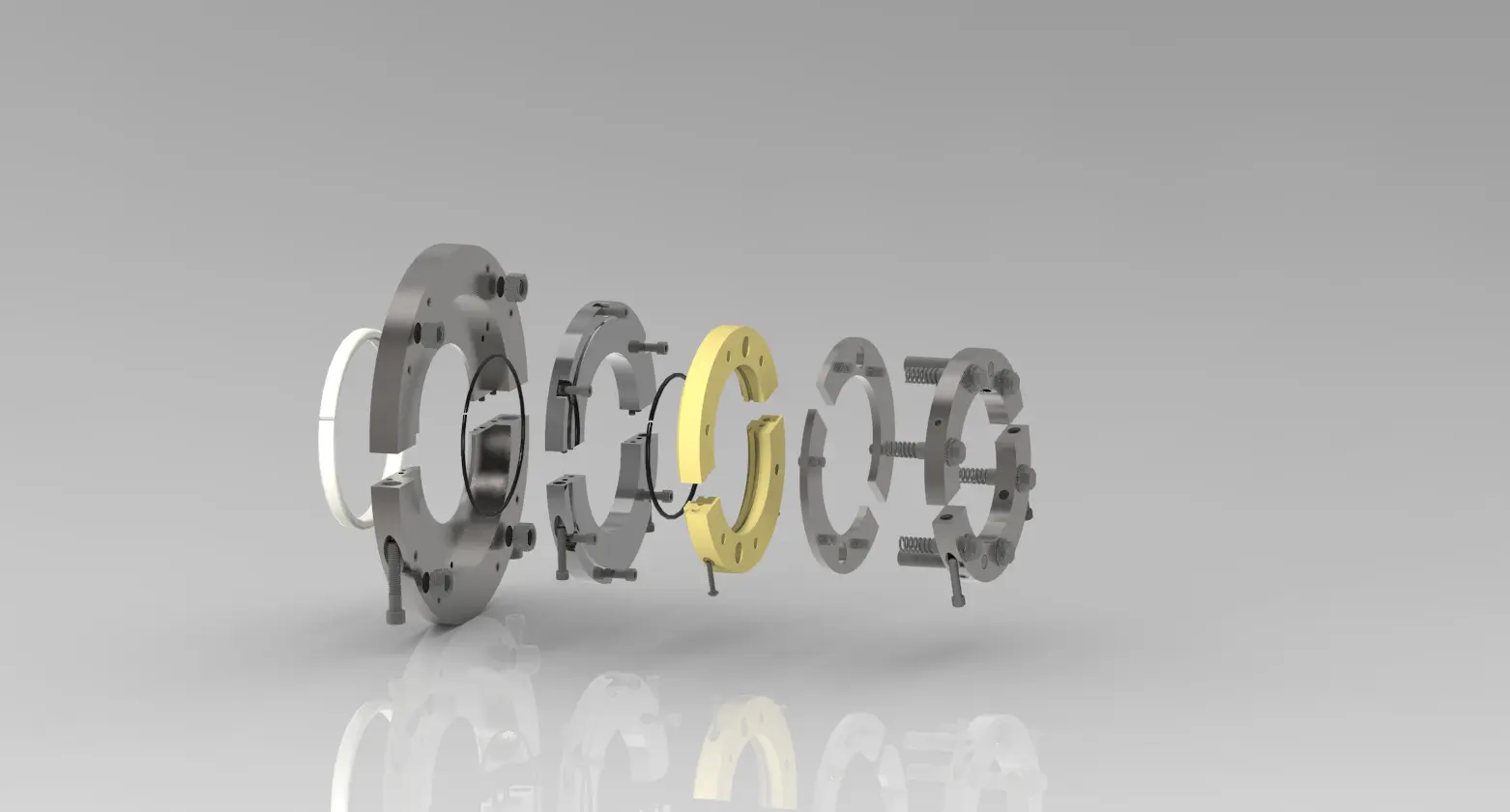

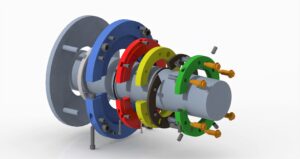

The MECO OFS Type-2 seal model replaces stuffing boxes, lip seal housings and other types of seals. It is made with a heavy, stainless steel housing and stationary seal face or stator that bolts directly to the machine at right angles to the shaft. A low-friction rotating seal face is in full contact with the stator. Sealing along the shaft is accomplished with an O-ring contained in the rotor that turns with the shaft and rotor. A drive collar, with large drive pins and self-contained springs, locks to the shaft at a predetermined distance from the rotor. Factory calibration is set by fully tightening the spring actuators, providing the seal face closing force.

Maintenance

The MECO OFS Type-2 seal model is easily maintained. The seal is easily disassembled for cleaning and resetting the spring load. By loosening the spring actuators, drive collar and rotor split-lines, the parts may be pulled back for inspection and cleaning. Reassembly sets the seal face closing force to original values. The external parts of the seal are easily hosed off following Good Manufacturing Practice (GMP).

Sizes Available

MECO OFS Type-2 seals are not inventory or “off the shelf” seals. They are custom designed and built to order and dimensions will vary according to each application. They are readily designed to fit most mounting arrangements specified by blender OEMs and are designer-friendly, to interface with customized, in-house process equipment requirements. Seals can be built either to S.A.E or metric dimensions.

Construction

Viton® is a registered trademark of E.I. Dupont de Nemours & Company

The MECO OFS Type-2 seal’s rugged components are designed for long life. Standard configuration uses a stainless steel housing enclosing a stainless steel stationary seal face. Rotors are made from a variety of FDA PTFE and PBT-based polymers. The standard elastomer for the O-ring is FDA Viton®. For highly-abrasive process materials, a replaceable stator insert, the polished central ring at left, can be offered. MECO seals can be fabricated from a wide variety of suitable materials.

Mounting

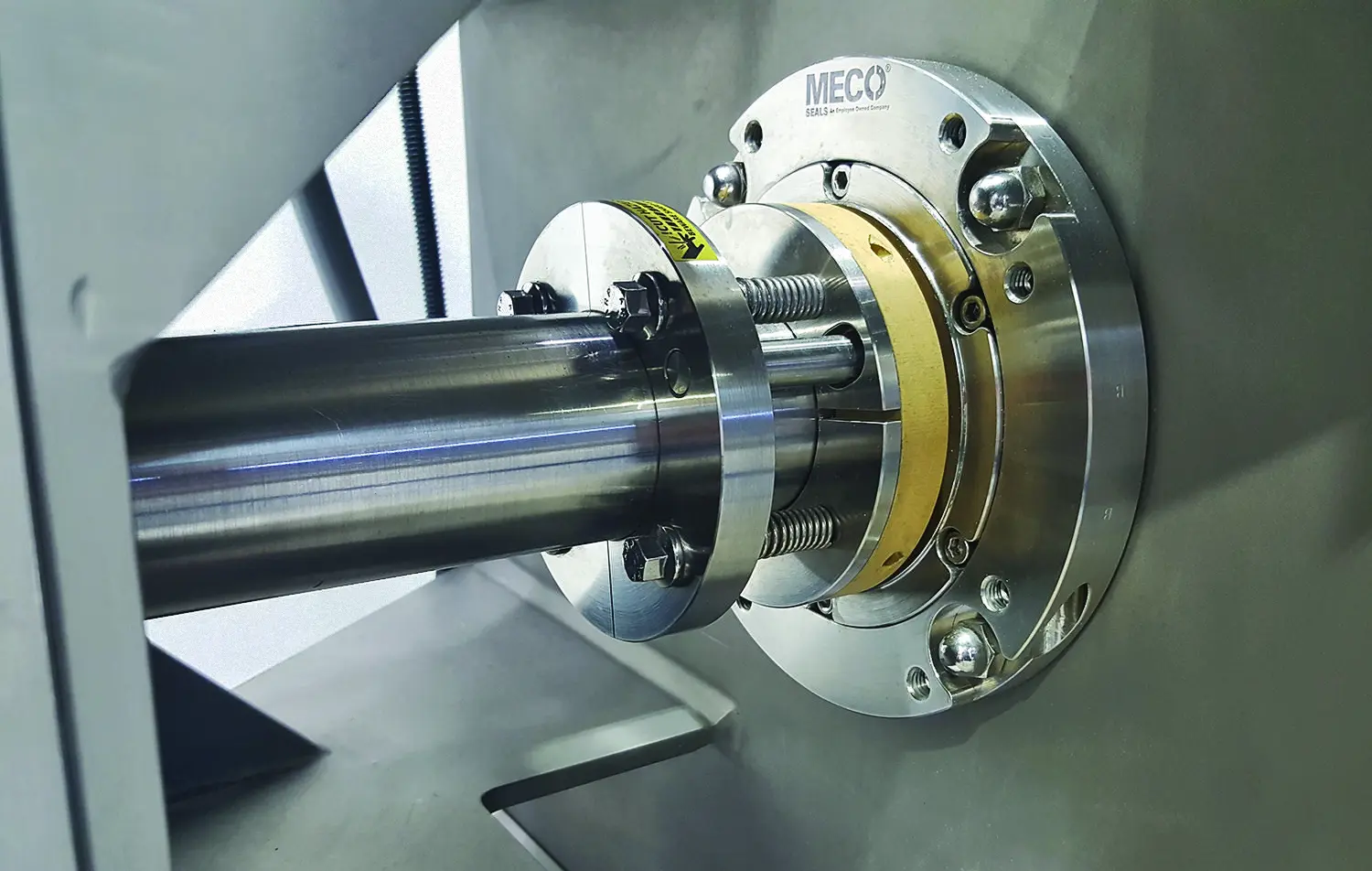

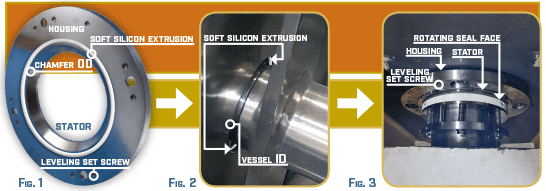

MECO offers “O”-rings following USDA guidelines or flat gaskets provided there is a machined, flat and square mounting condition. Otherwise, bedding compounds or a commonly used soft, FDA silicone extrusion adjusted with setscrews in the housing form a true mount both flat and perpendicular to the shaft. Many mounting surfaces are on equipment heavily welded during fabrication, which can cause the seal housing to warp on installation. The extrusion approach corrects the problem -an example is shown below (Figures 1-3).

Specifications

Specifications

| Mechanical Capabilities | |

|---|---|

| TEMPERATURE | -60° to 300° f (-50° to 149° C) – varies with size and speed |

| PRESSURE | Vacuum to 10 psig (70 kPa) |

| Shaft Speed | Up to 290 RPM |

| Total Indicator Runout (TIR) | 1/4″ (6mm) standard; greater runout can be accommodated |

| Repeated Axial Shaft Motion | 1/64″ (0.4mm) |

| Thermal Shaft Growth | 1/8″ (3mm) typical; actual limits are set by physical space and application parameters |

Results may vary with operating conditions – please call for discussion.

Documentation

Need More Information or a Custom Quote?